Slowly adding notes to all the images…

Oh Facebook marketplace and your great deals….

“1955 Willys 1 ton pickup under restoration. Original super hurricane engine runs but burns oil, transmission is solid as well as 4 wheel drive. I’ve recently put on new brakes, brake lines, master cylinder and front hubs. New BF Goodrich A/T tires with less than 200 miles. I’ve purchased a complete engine kit and some incidentals that will be included with the sale. Title in hand. Please no lowball offers and I’m not interested in any trades. Recent events have forced me into selling my truck.”

Let’s break this down with a bit of foreshadowing…

1955 Willys 1 ton pickup under restoration.

“Restoration” is a loose term.

Original super hurricane engine runs but burns oil

They always do…but not for the reason this one did.

transmission is solid as well as 4 wheel drive.

Refreshing Truth!

I’ve recently put on new brakes, brake lines, master cylinder and front hubs. New BF Goodrich A/T tires with less than 200 miles.

Truth!

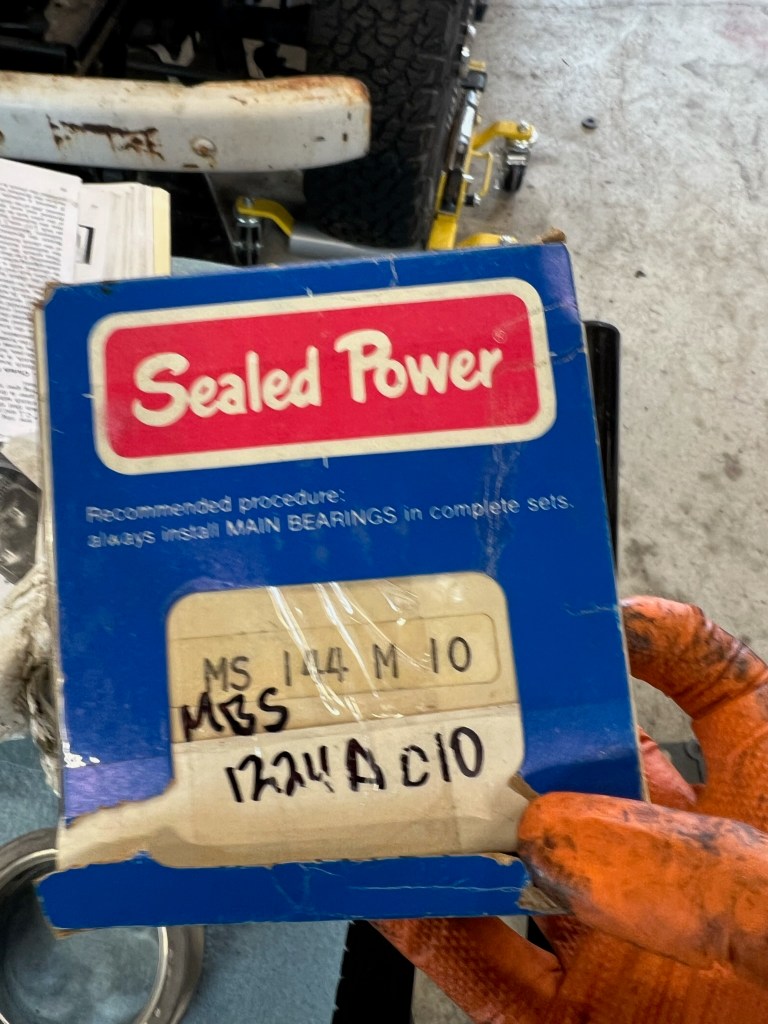

I’ve purchased a complete engine kit and some incidentals that will be included with the sale.

*Engine seal kit.

Recent events have forced me into selling my truck.”

Quote ” I have too many projects and I need to sell this one”

I feel you buddy, I really do, now time to do it to myself. The magnetism of a $5000 1955 Willys Pickup in decent running condition was too hard to pass up. With a line of 5 people test driving it that day I was first in line, there was also pressure to not miss out.

…and, like every general money pit starts and ends….a trip to Uhaul for a car hauler…and brought it home!

Doing some digging the previous owner bought this out of VA a couple years before… the truck lived its life in VA as a logging hauler on their personal property. It was fixed up in the early 2000s, frame reinforced and some misc other work performed at that time.

OLD FACEBOOK SALE PHOTOS FROM VA

Back to photos as I received it.

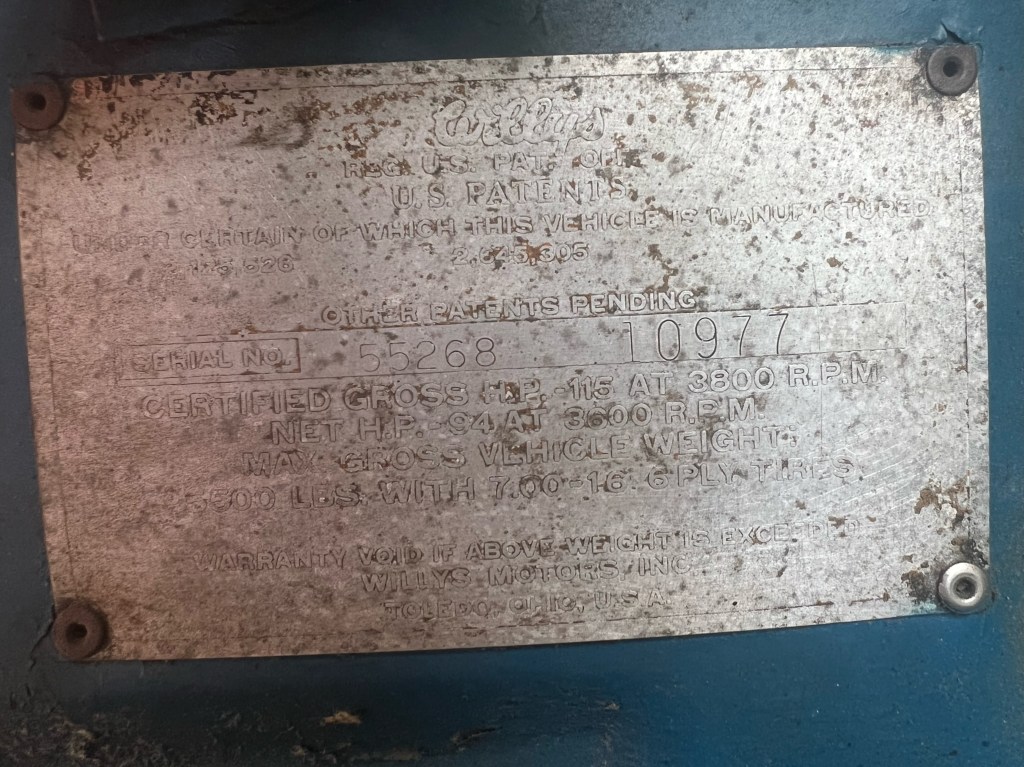

Original Number Plate

Already enjoying itself on our dirt roads…minus the overheating…bad running at altitude and vapor lock….

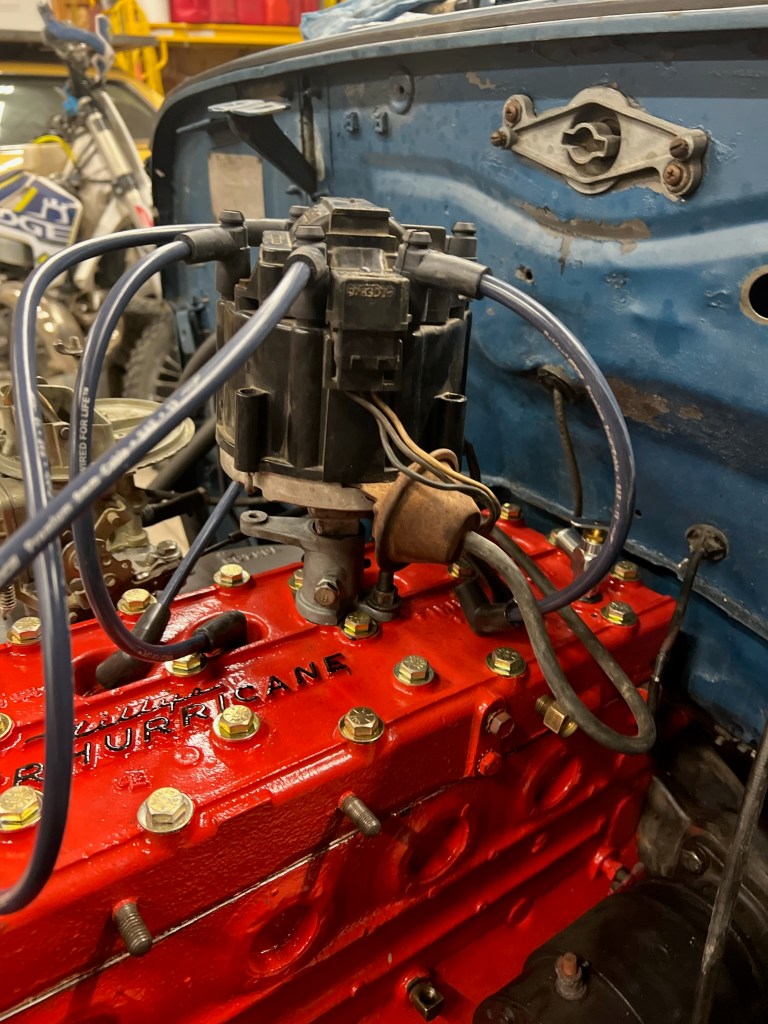

Continental 6-226 Flathead!

You don’t see these often. Factory option Warn Overdrive likely put on in the 1960s with provision for a rear PTO still!

Adapter to run a GM HEI Distributor off of a 1970s GM Straight 6.

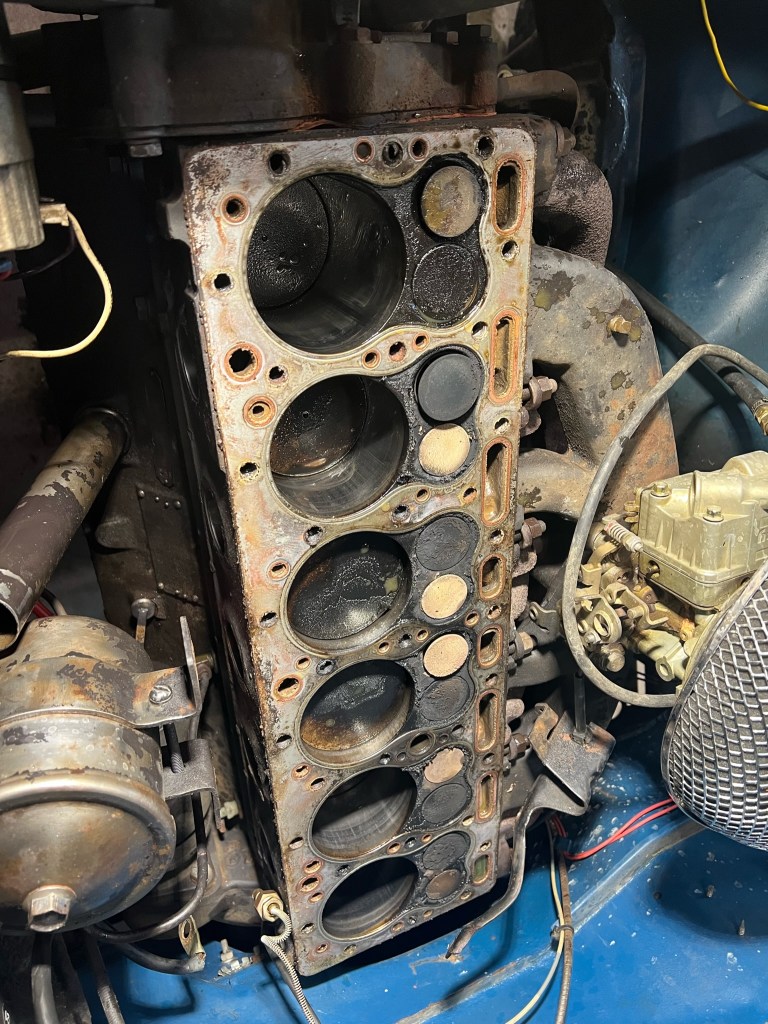

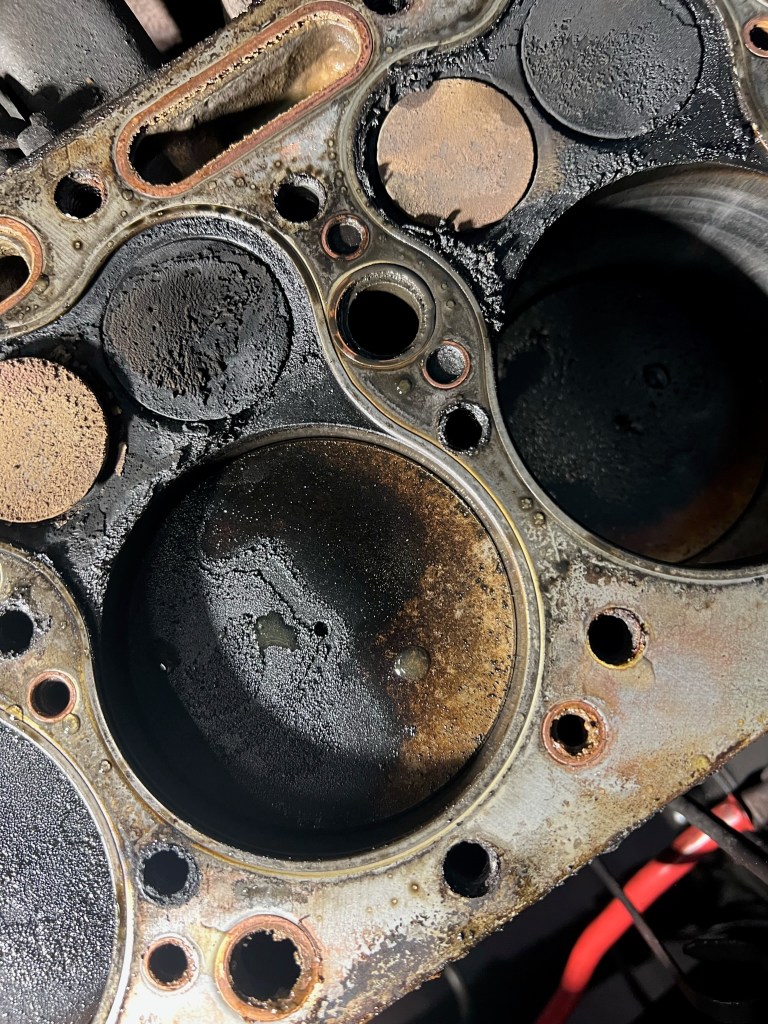

After a lot of bad running I open her up to figure out what the hell is going on. It’s not great, but its a work truck that’s had a hard life. Clearly the head gasket was leaking, not surprising on a flathead like this. Years of carbon build up also present. I believe the previous owner wasn’t running lead additive in the gas and also smoked the exhaust valves which you’ll see later.

Cylinder 1

Cylinder 2

Cylinder 3

Cylinder 4

Cylinder 5

Cylinder 6

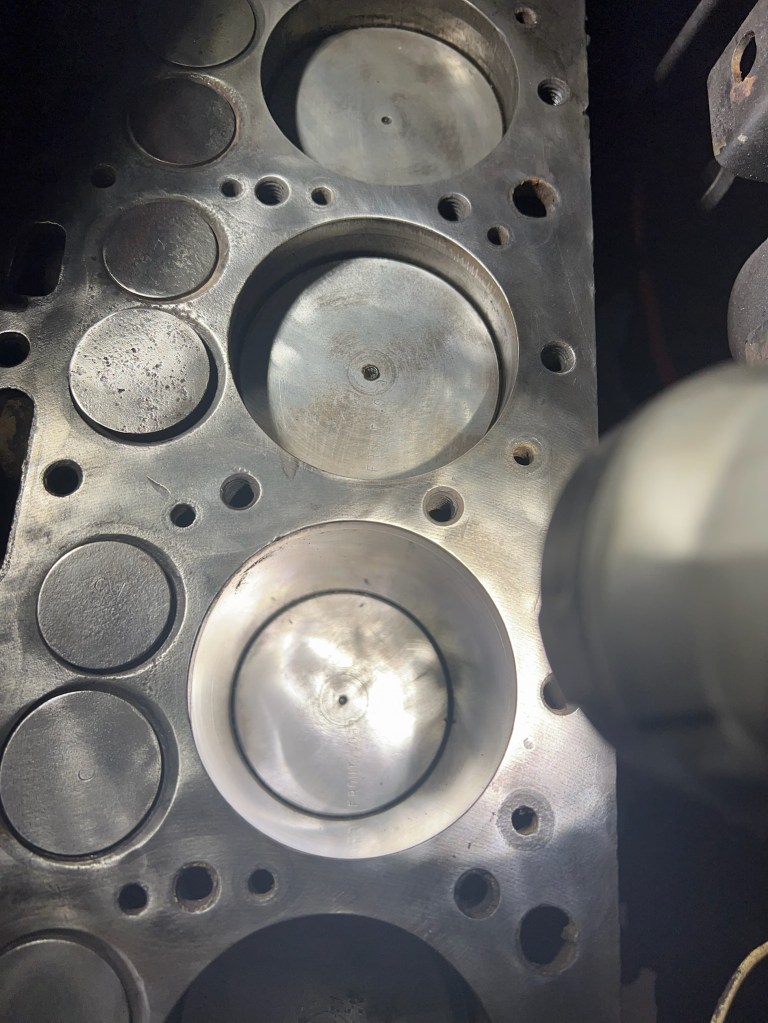

A quick cleanup of everything

Once cleaned up you can see this engine was rebuilt at sometime with .030″ over pistons. Valves appear to be original.

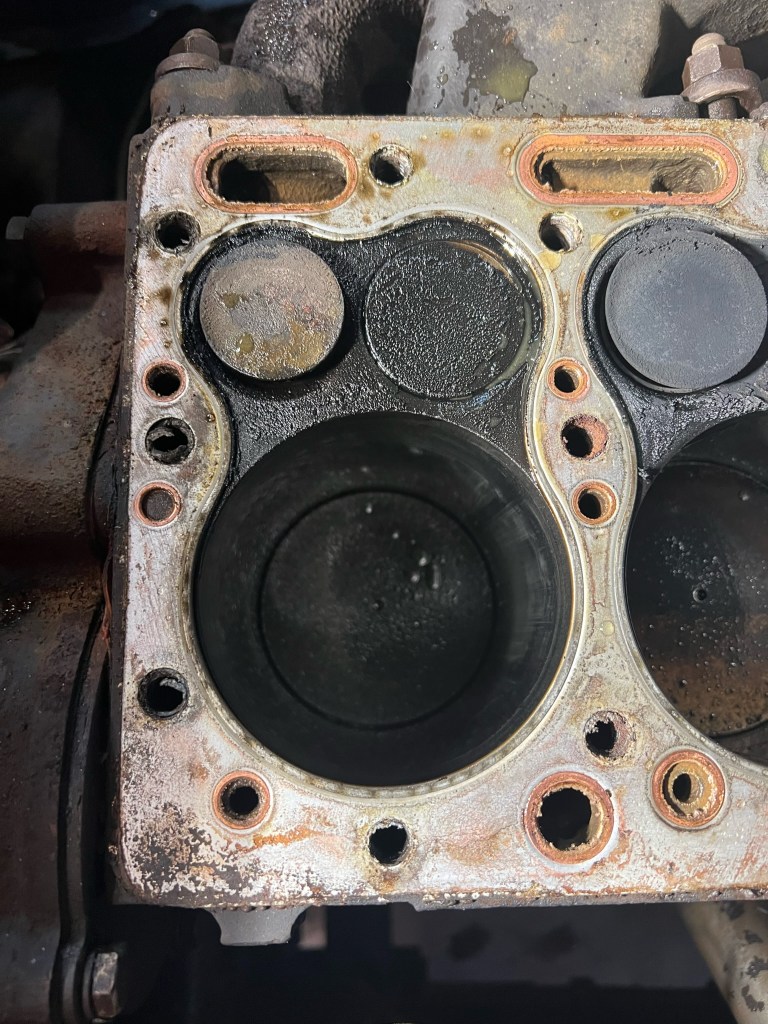

Pulling off the hold head gasket, you can see the burn markets between cylinders 2-3-4-5

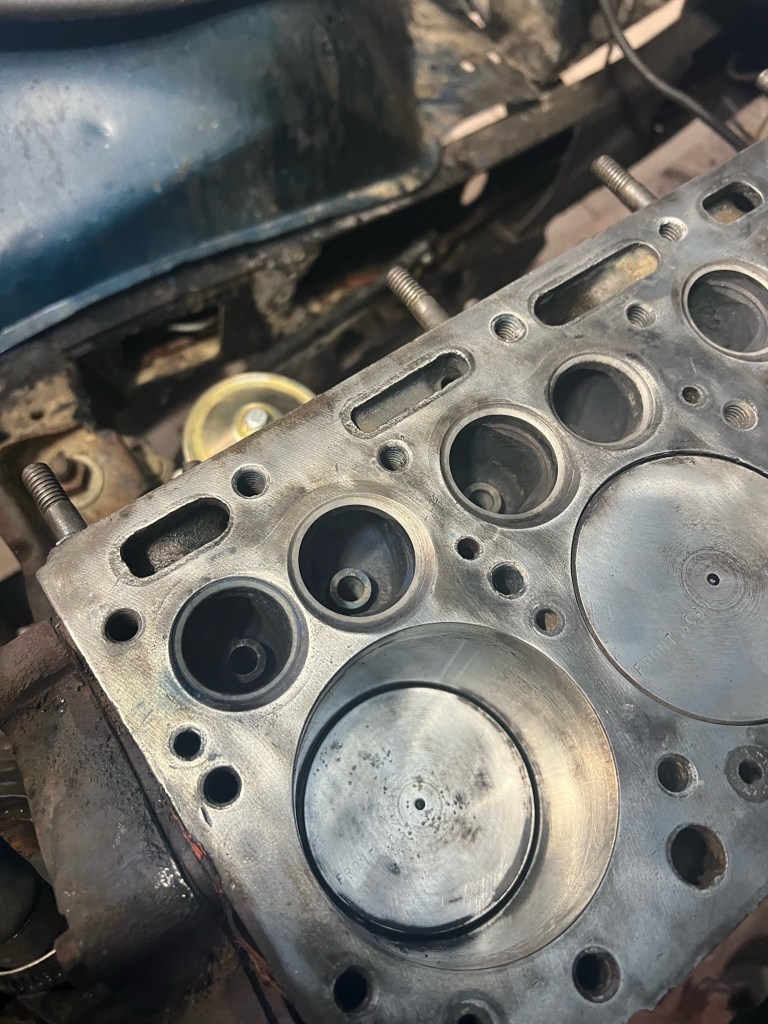

Starting to look at the valves and valve seats.

Intake valves looked ok after clean up, lets see after lapping the exhaust.

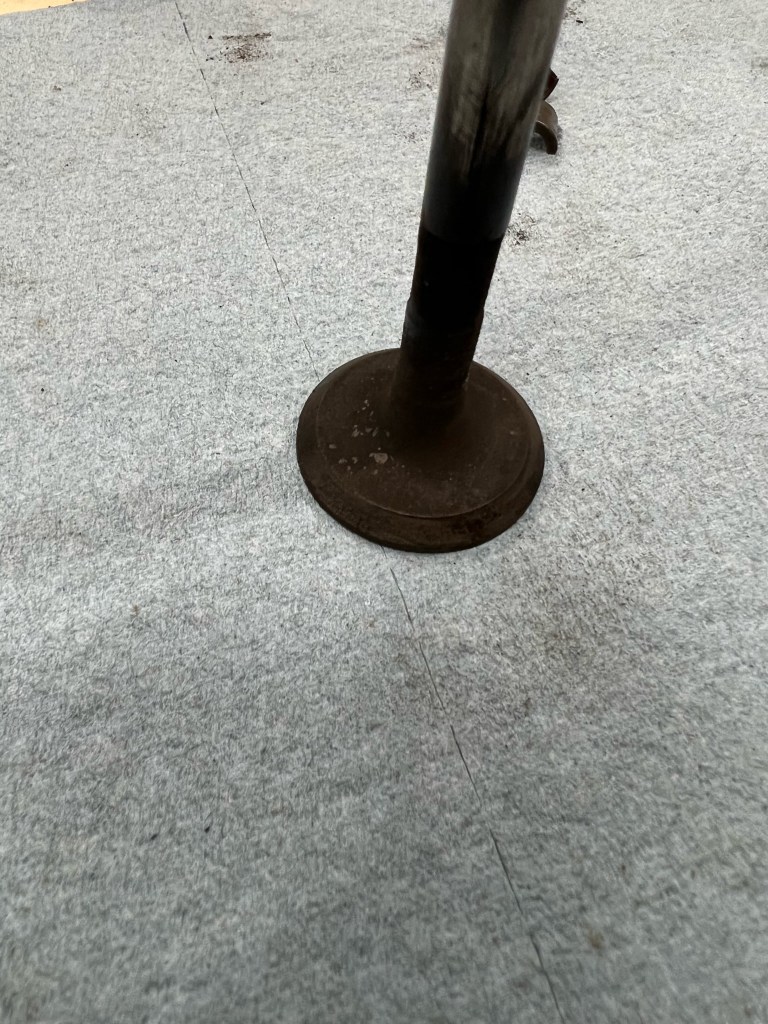

Checking valves for straightness.

Exhaust valve seats not in a great spot.

Cylinder 1 exhaust seat cleaned up decently.

Blue mark up fluid everywhere as I was working valve to valve.

A very burned exhaust valve. This will need to be replaced.

Lapped valve seats throughout.

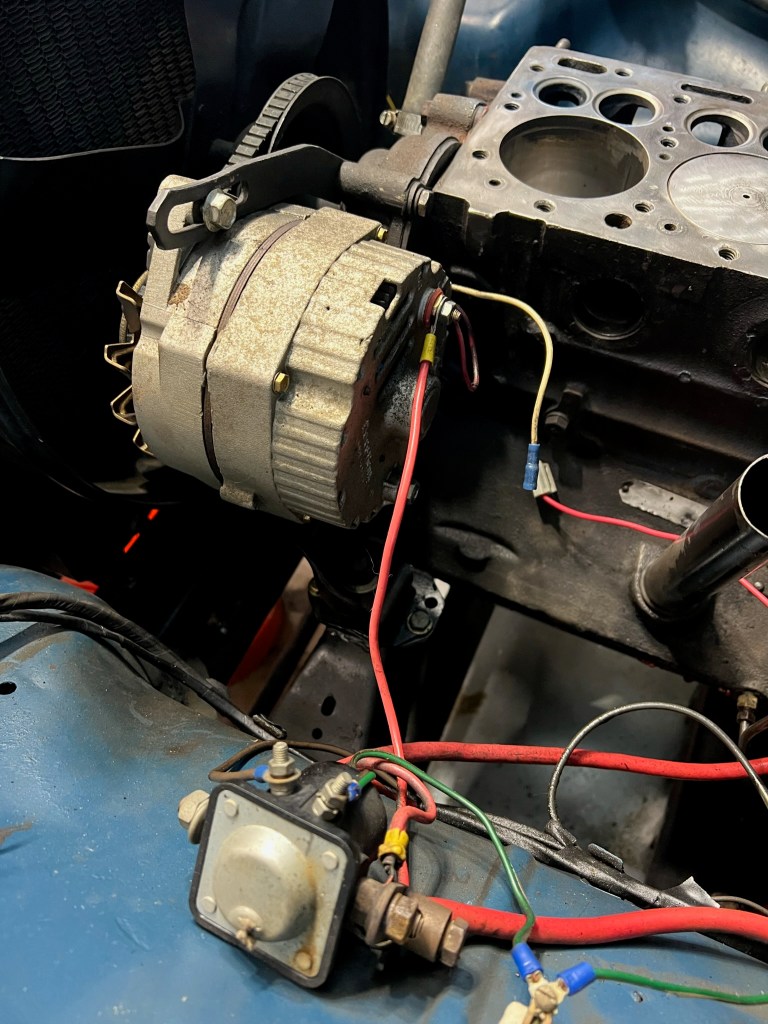

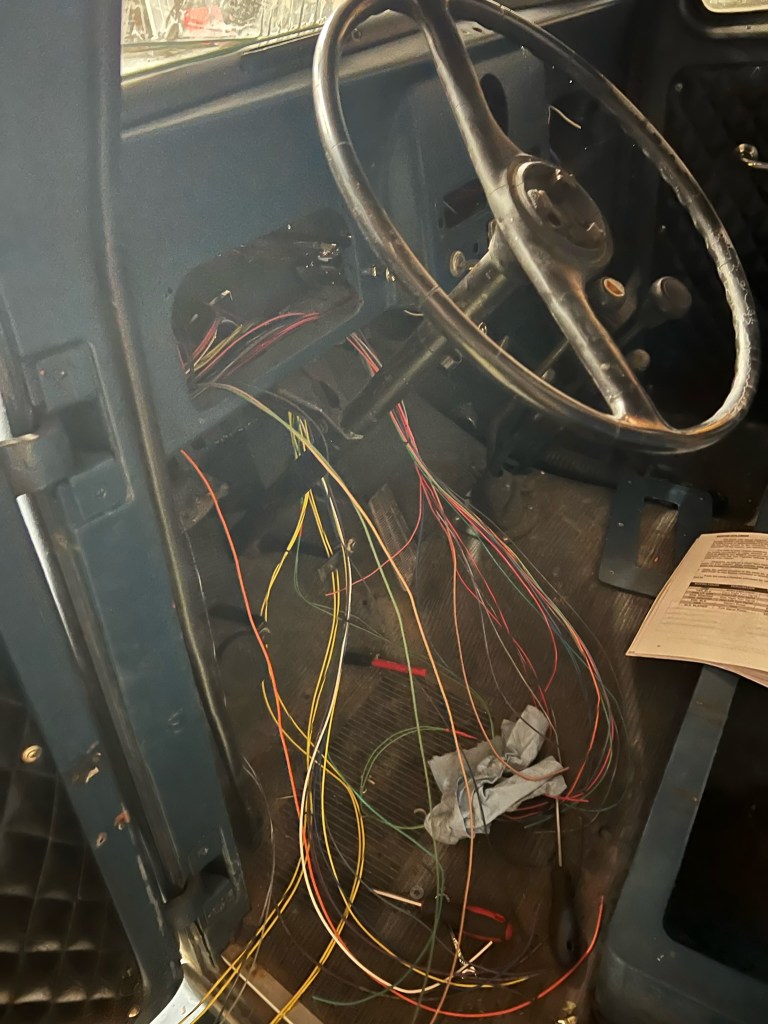

Shit show wiring being torn out and replaced.

A very shittly welded bracket to modify a GM 1wire alternator to the engine. This was fixed up before going back in.

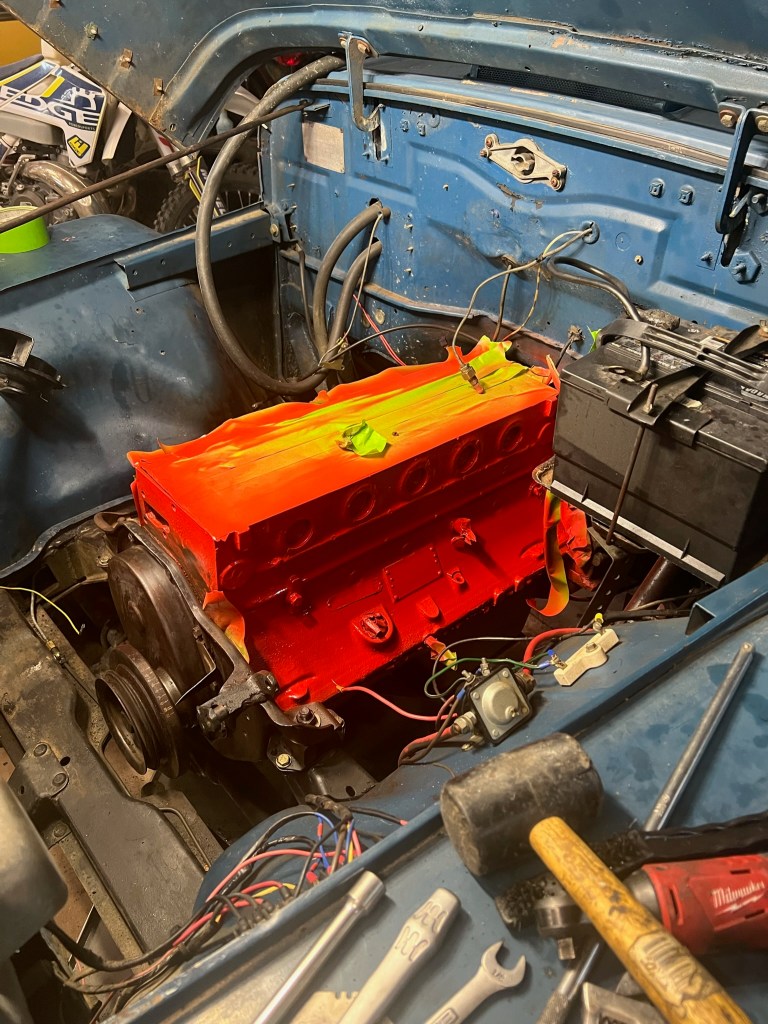

Craigslist rebuild in progress. Gotta get that red in and clean some things up!

Doing a bit of force patina on the body line details of the vehicle. Paint was already fading so I thought i’d assist it a bit to highlight the character.

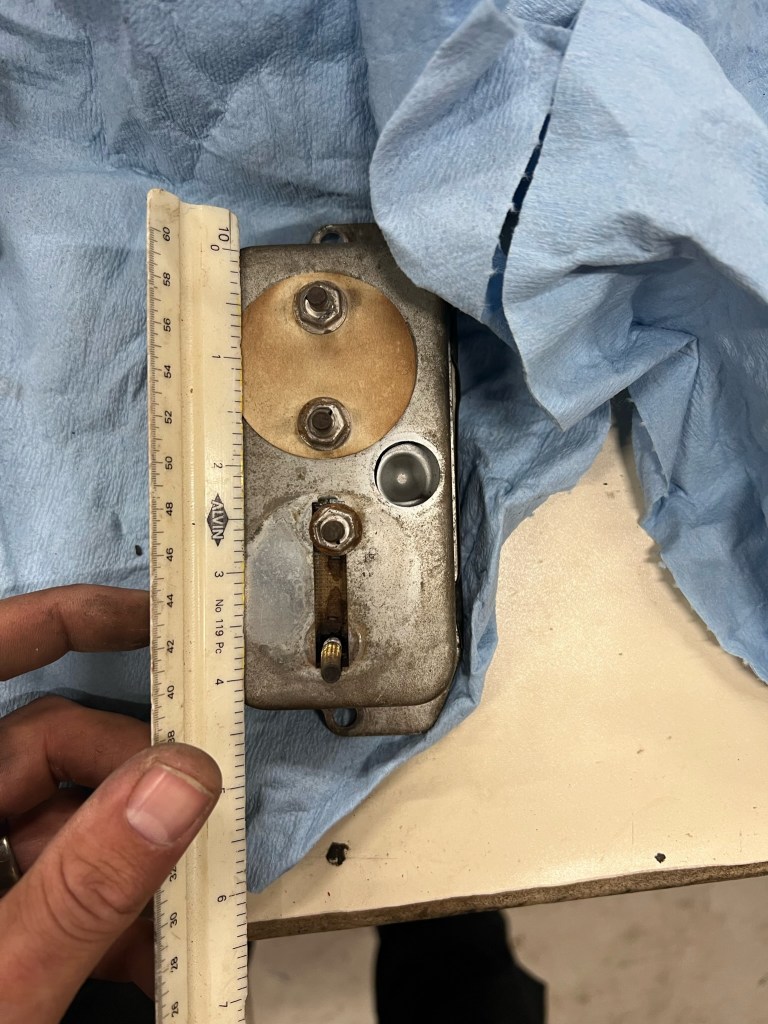

Rear main seal shit show discovered. Old rope seal on a warped seal block.

Decided to replace the valve guides as well. These were a massive pain in the ass to remove and took a long time. Full destruction on a few of them.

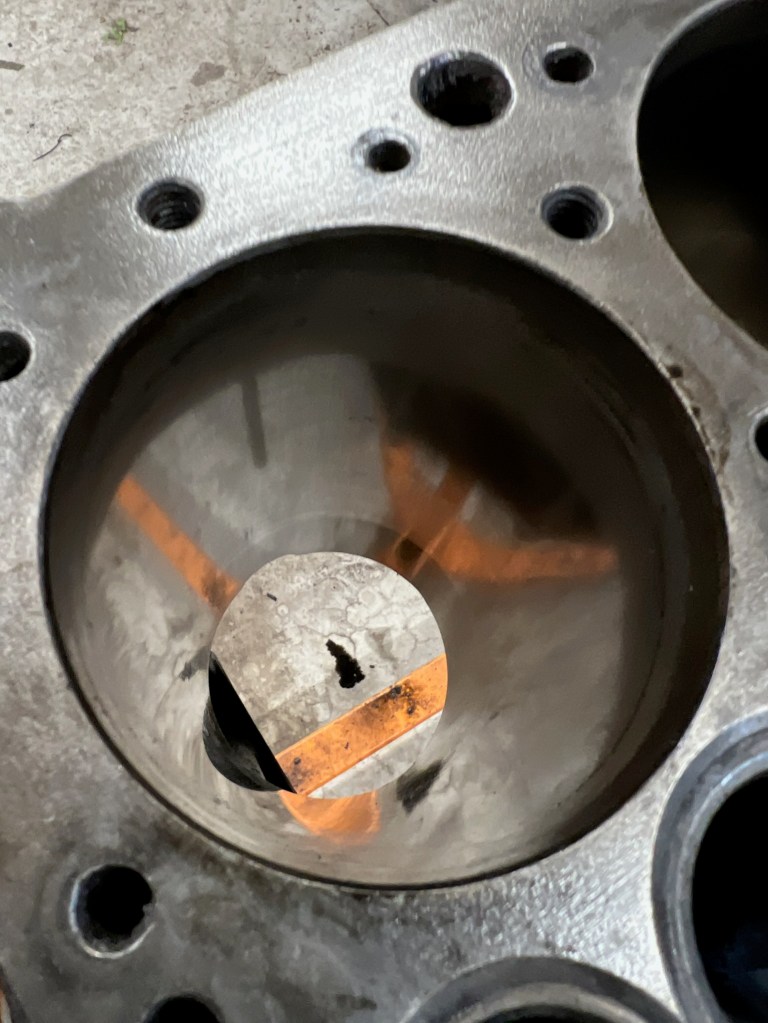

Well fuck, a small crack discovered between the exhaust valve and cylinder. This is one of the major issues with boring the old engines .030 over.

Valvetrain organization

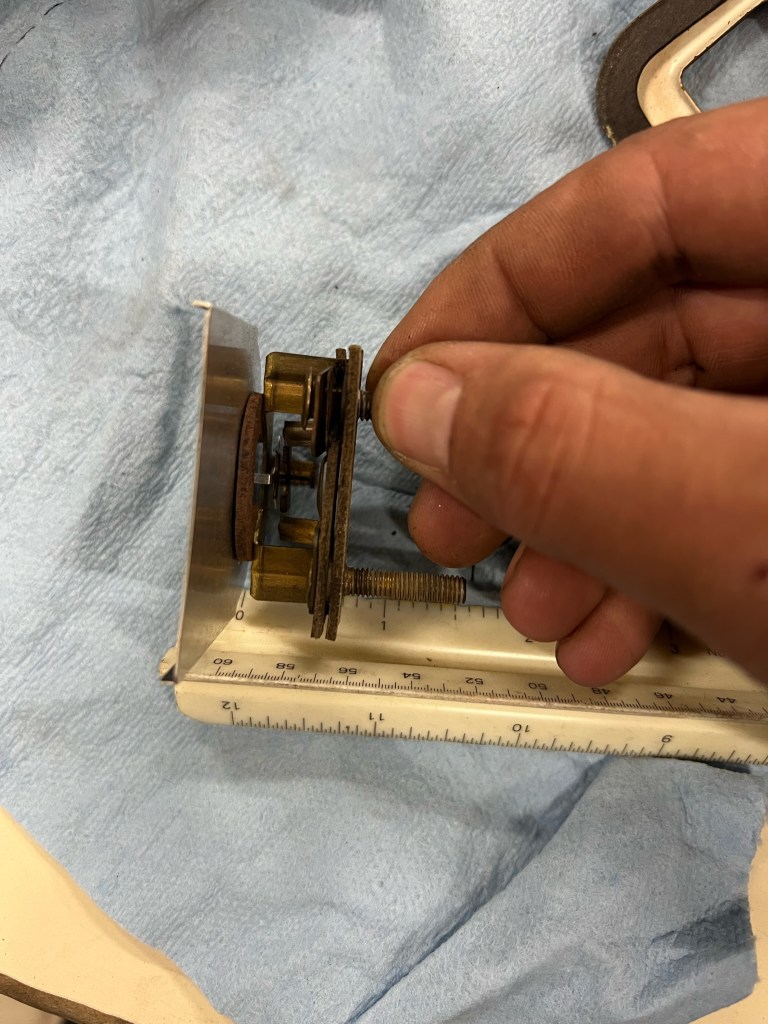

Custom valve seat driving tool I made for this.

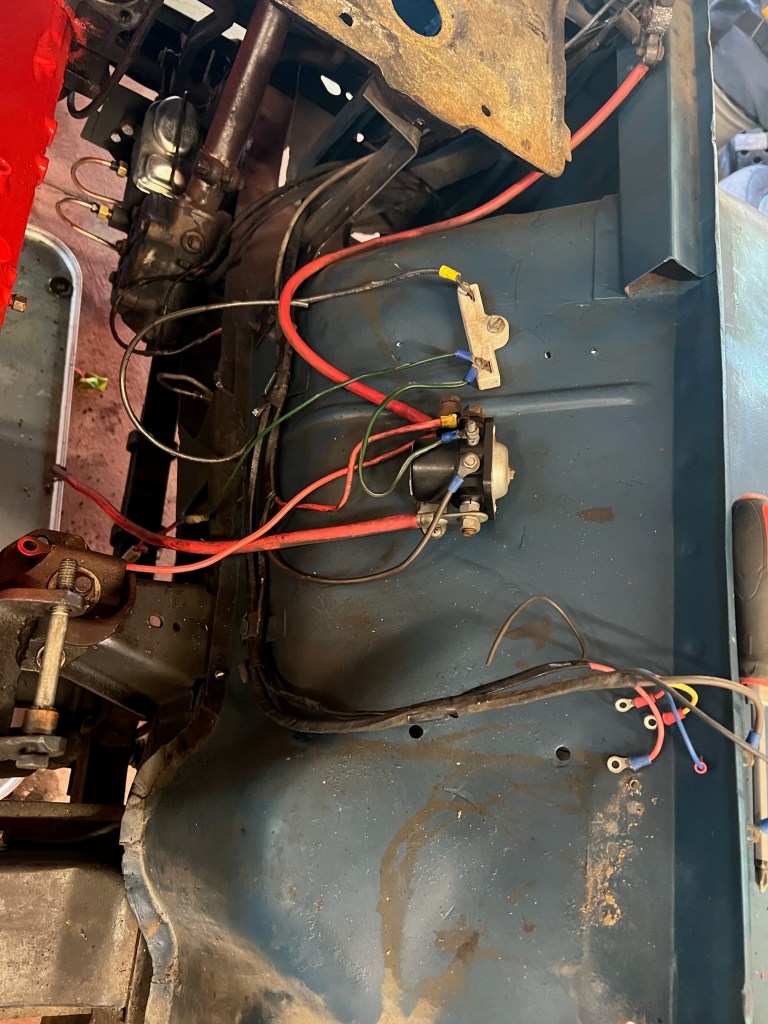

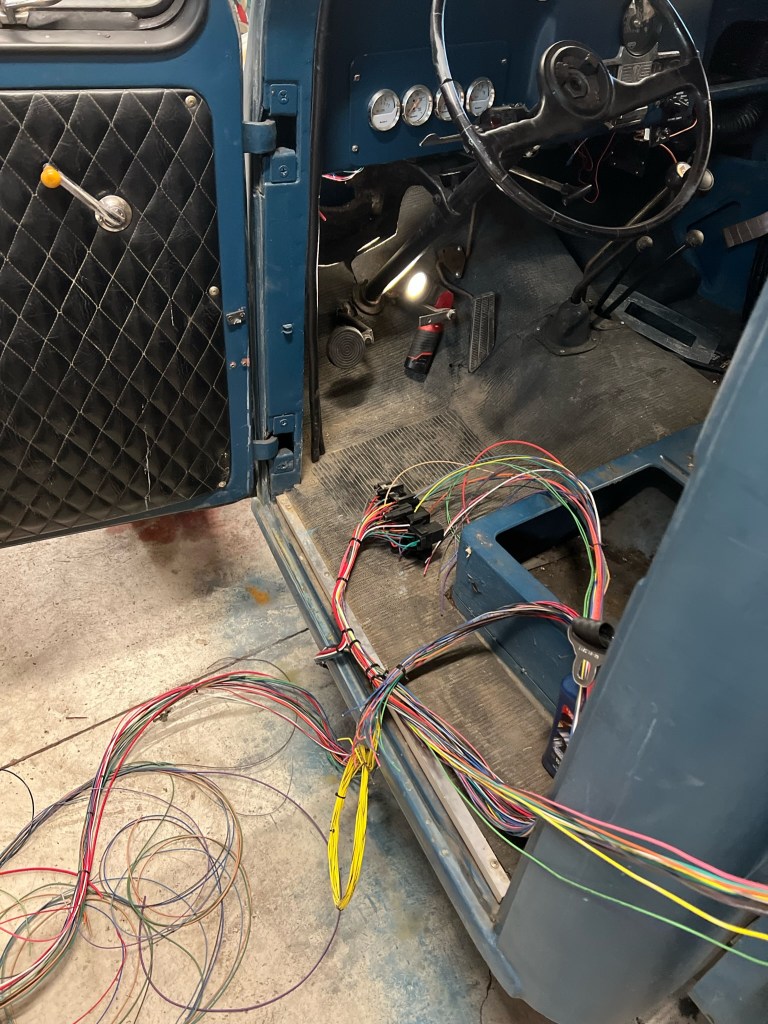

Starting to rewire the whole vehicle.

Bye bye, pile of shit.

EEK.

Burn it all.

Universal Painless wiring harness which will be modified for all the upgrades.

Lapping the new exhaust valves to the seats.

Engine going back together…but not for the last time!

Working on the Gauges and swapping the AMP meter guts to a Volt Meter for the more modern wiring and alternator.

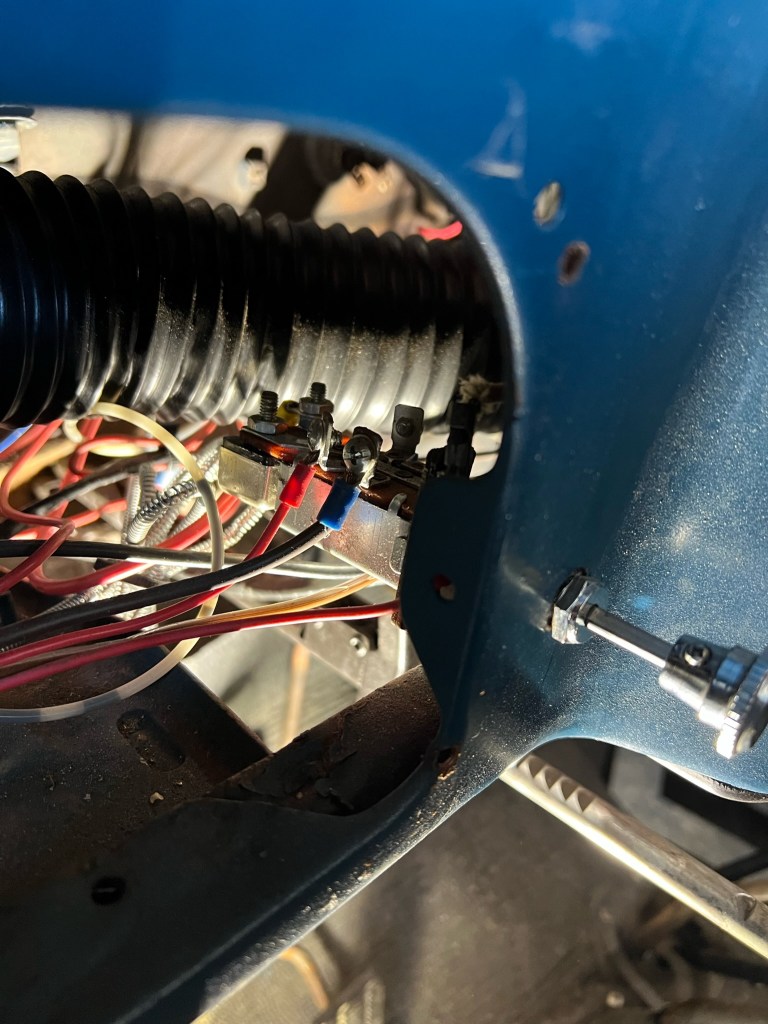

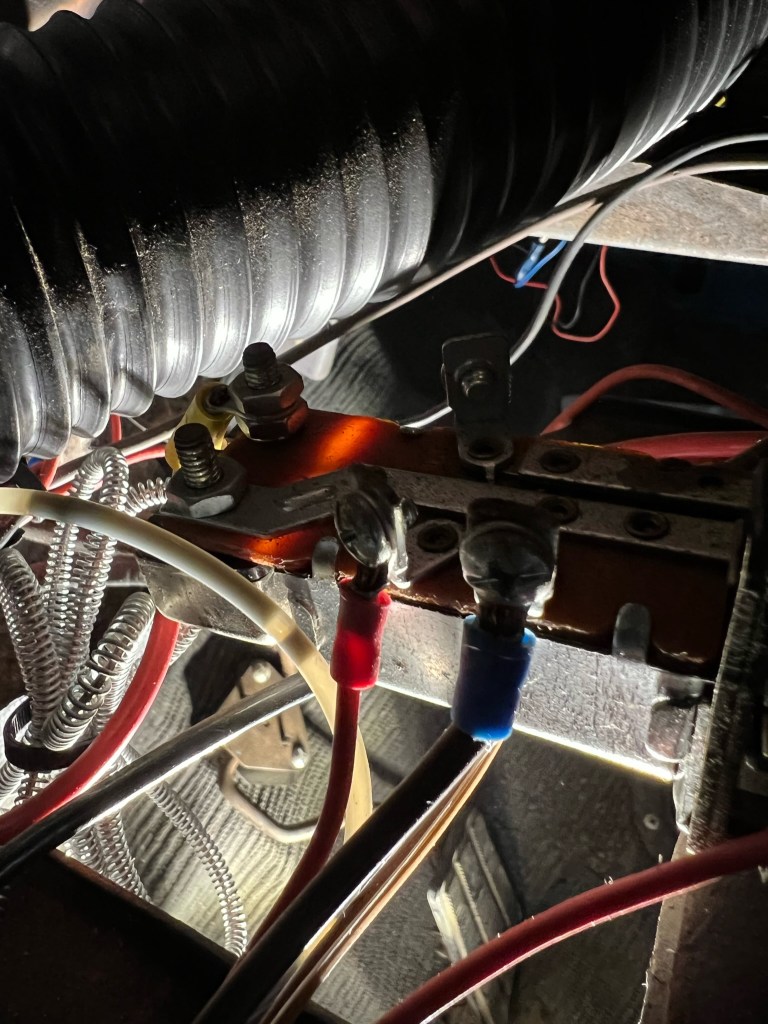

Starting to clean up all the wiring the right way.

These are a must have. Absolutely amazing.

Wiring cleaned up on one fenderwell with GM style waterproof connectors.

Solenoid, fuse block and all engine wiring tucked up under the battery. Such an improvement.

Starting to run the cab wiring.

Poor girl I saw in the junkyard looking for something..

THIS!!!! 1970s ford 9″ in the right width, bolt pattern and perch width. WOOOHOOOO

Ripped out and ready for a new life.

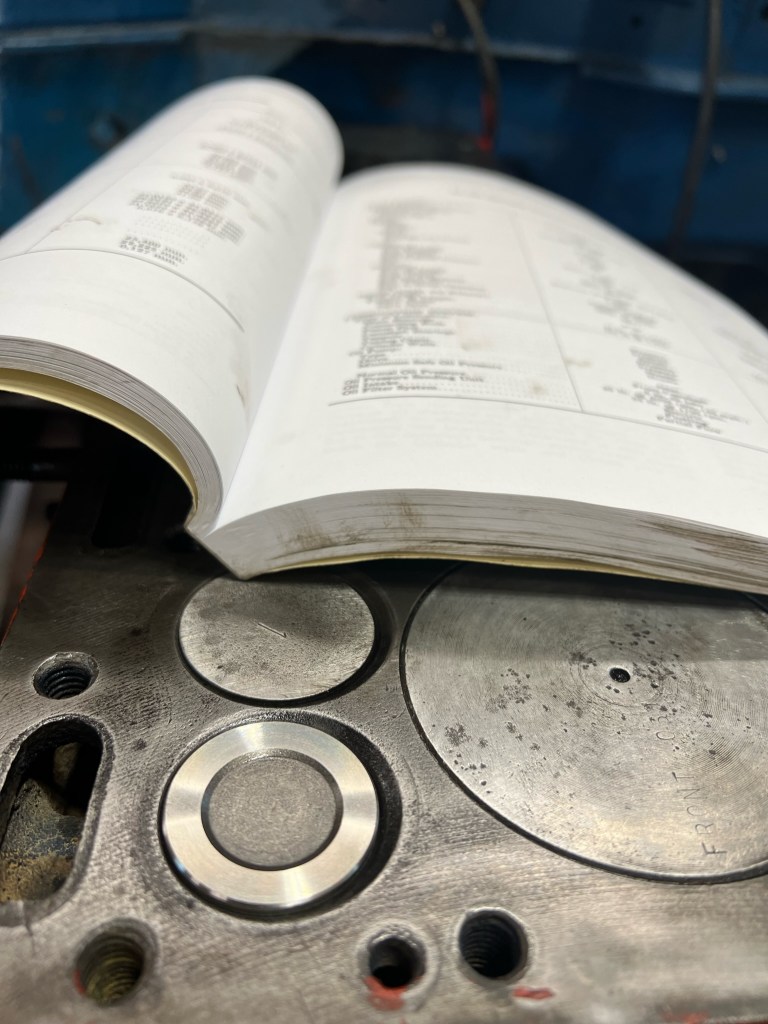

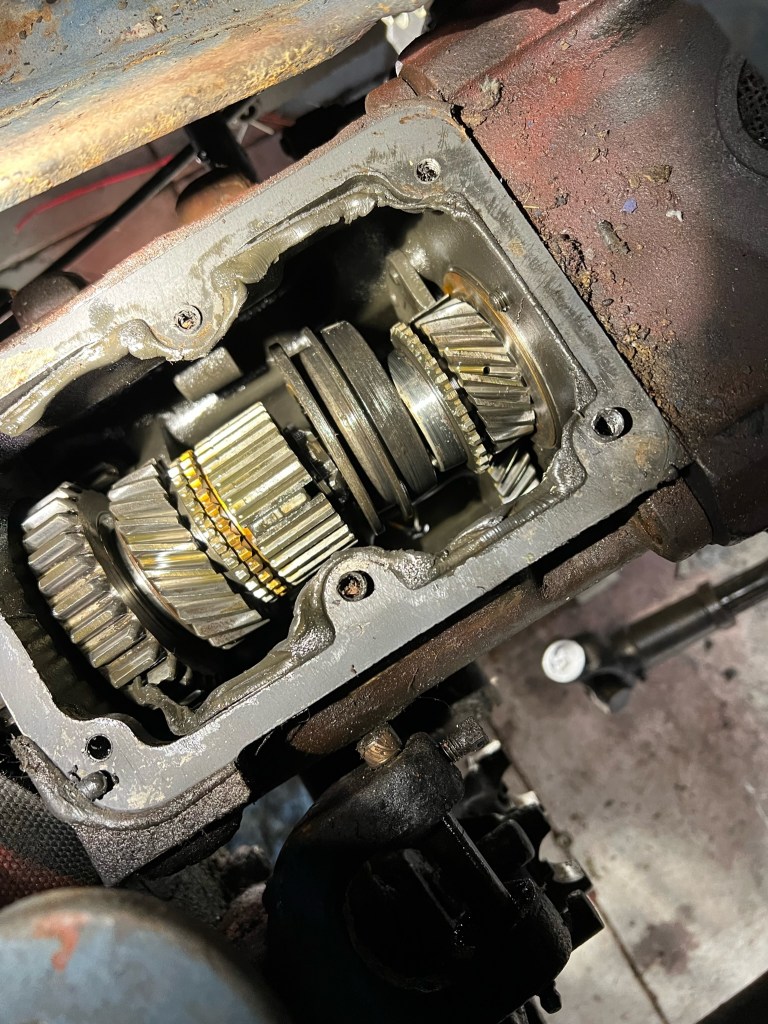

Reference photo for the trans and transfercase before rebuild.

Welp, surprise. After all that engine work, something is still not right and I can’t for the life of me figure it out. Out comes the engine.

And off to a dude who knows these things.

This is Roger. Haven’t checked in with him for years, but at the time he was probably the only dude alive who had rebuilt these engines for close to 50 years. Fun fact, most of the old oil rigs across Utah have been maintained by this guy since the 70s and run the same continental 6-226 as the willys truck. He discovered there was a cylinder wall crack lower down that was really hard to see without knowing what you are looking for. OOPS. Check our this guy’s shop, all vintage flatheads.

So, with a cracked block, there wasn’t much to do without finding a new engine, so I tracked down an original running one out of Colorado with the high compression head.

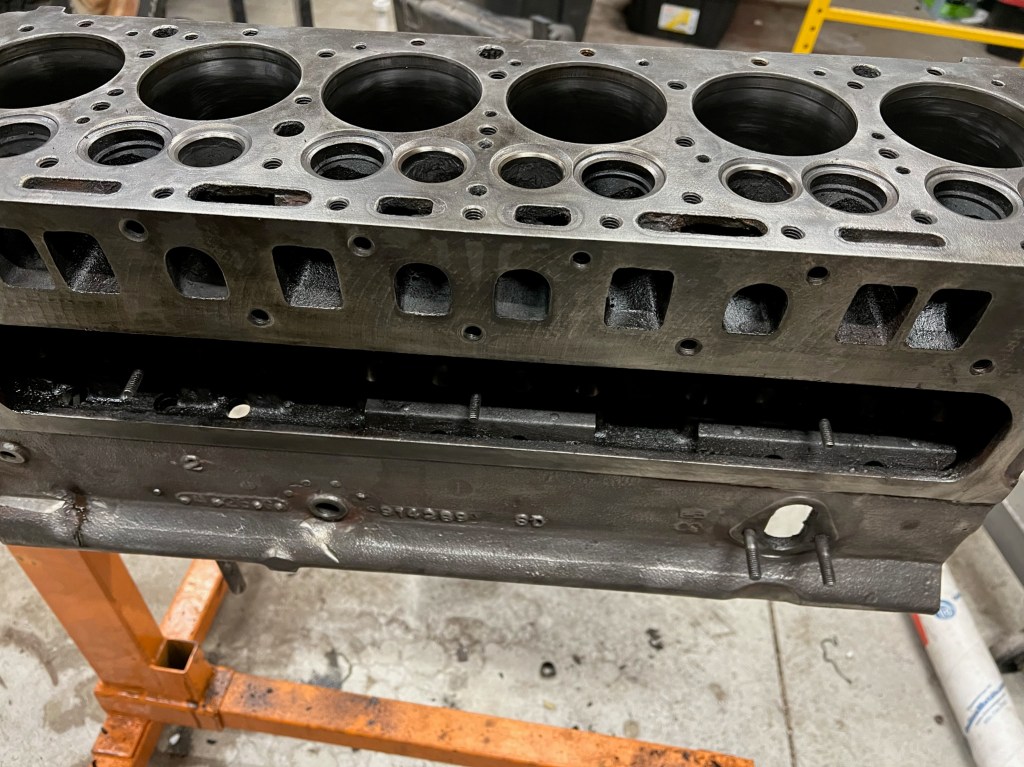

At this point, I’m now doing a full teardown and re-machine.

This engine is in much better condition and I’m going through it with a finer tooth comb.

All bearing clearances were checked before I even took it in for machining.

Full teardown.

Insane factory ring gap. Not sure if this was someone replacing rings at some point in time, but this was certainly burning oil.

More tear down organization.

Glazed but good condition.

Bearings not bad.

Pulled all studs out of the block.

Andddddd shes back!

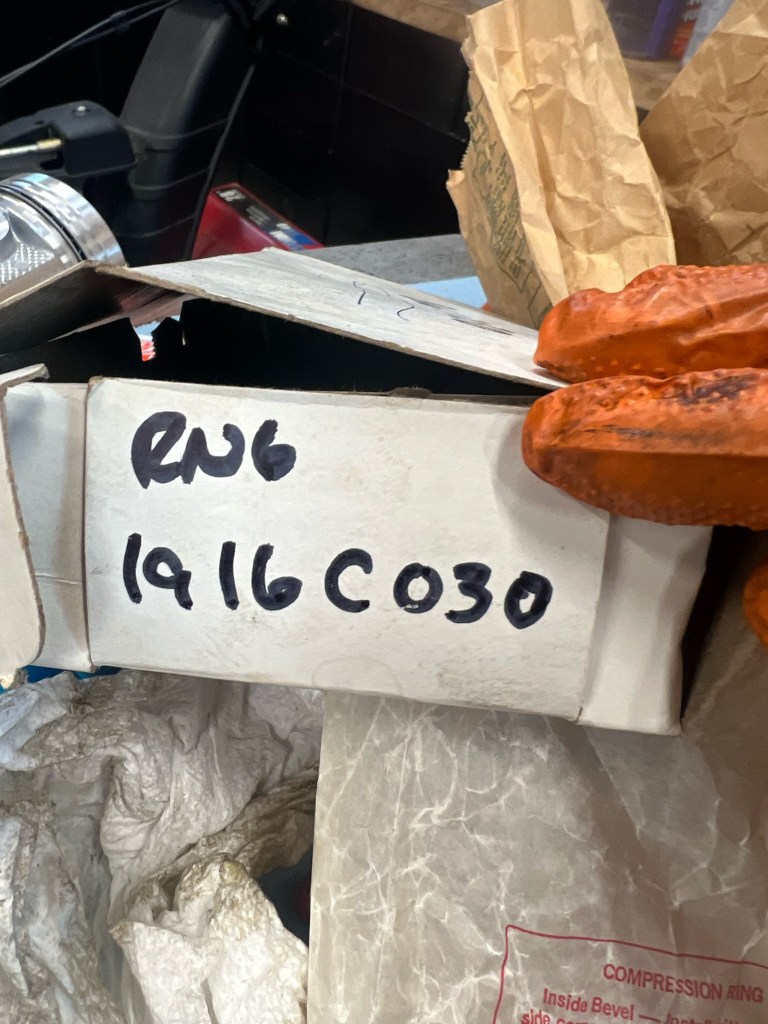

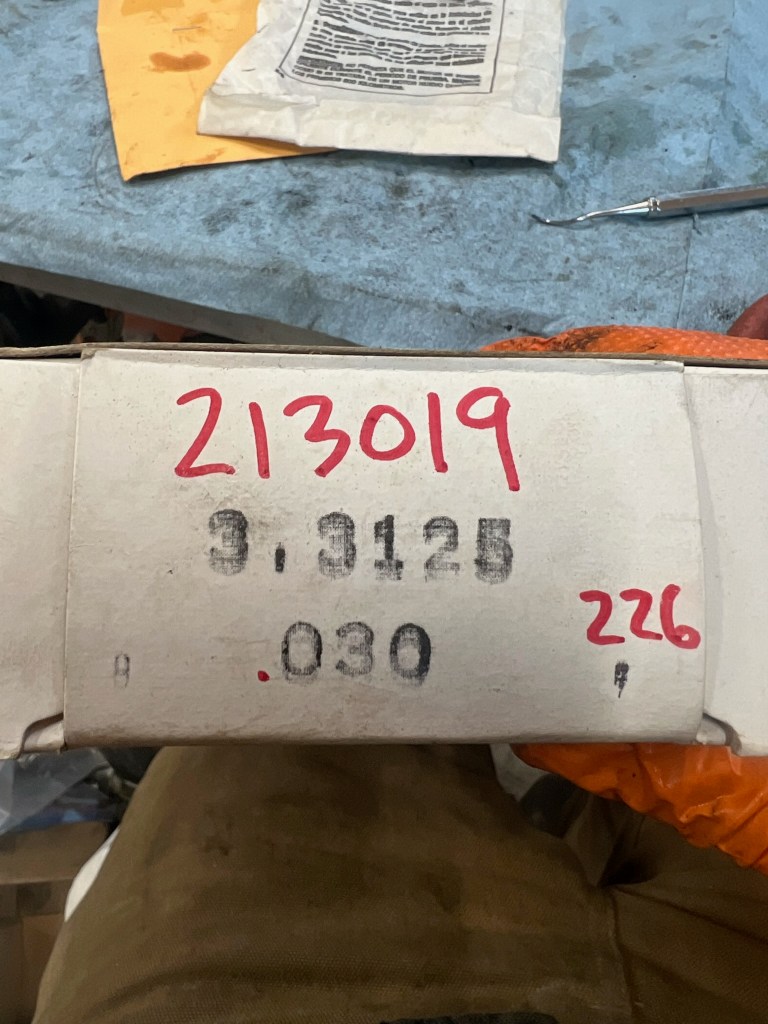

Bored .020 over, new modern steel exhaust and intake valve seats, fully crack tested and the crank shaft cleaned up and ground. Beautiful.

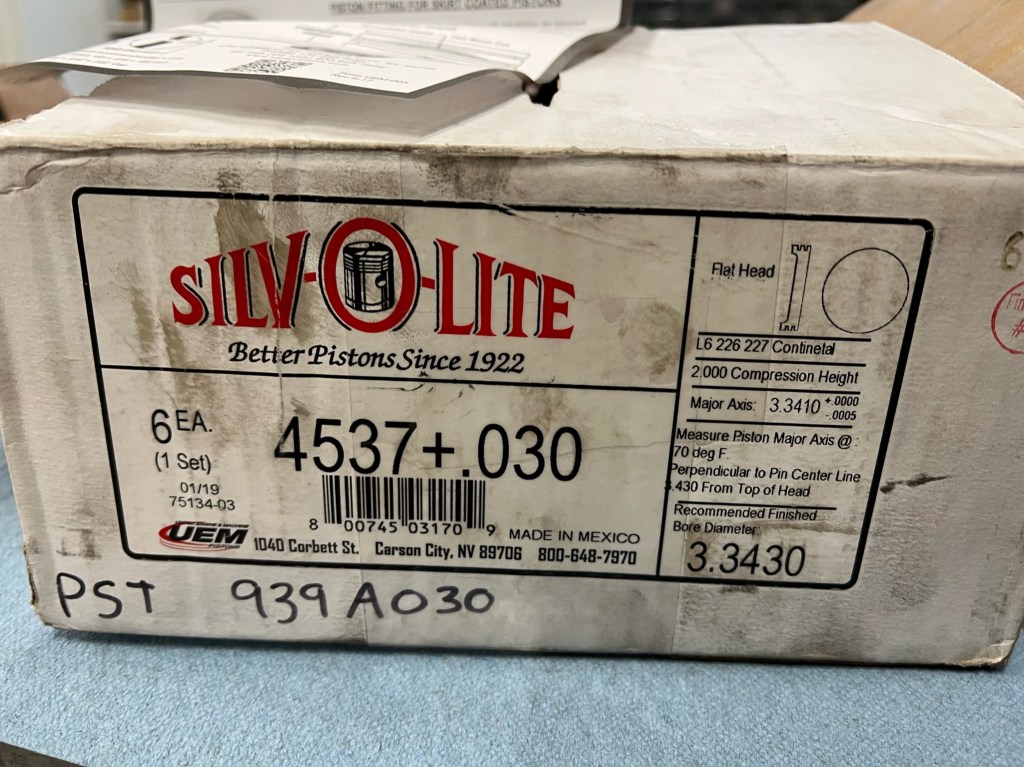

New old stock pistons, but the wrong ones ordered by the shop doing the machine work. New ones were then ordered.

Schnieder racing cam regrind notes. My buddy there modified it a bit to allow the valves to stay closed longer to help build up compression better at altitude.

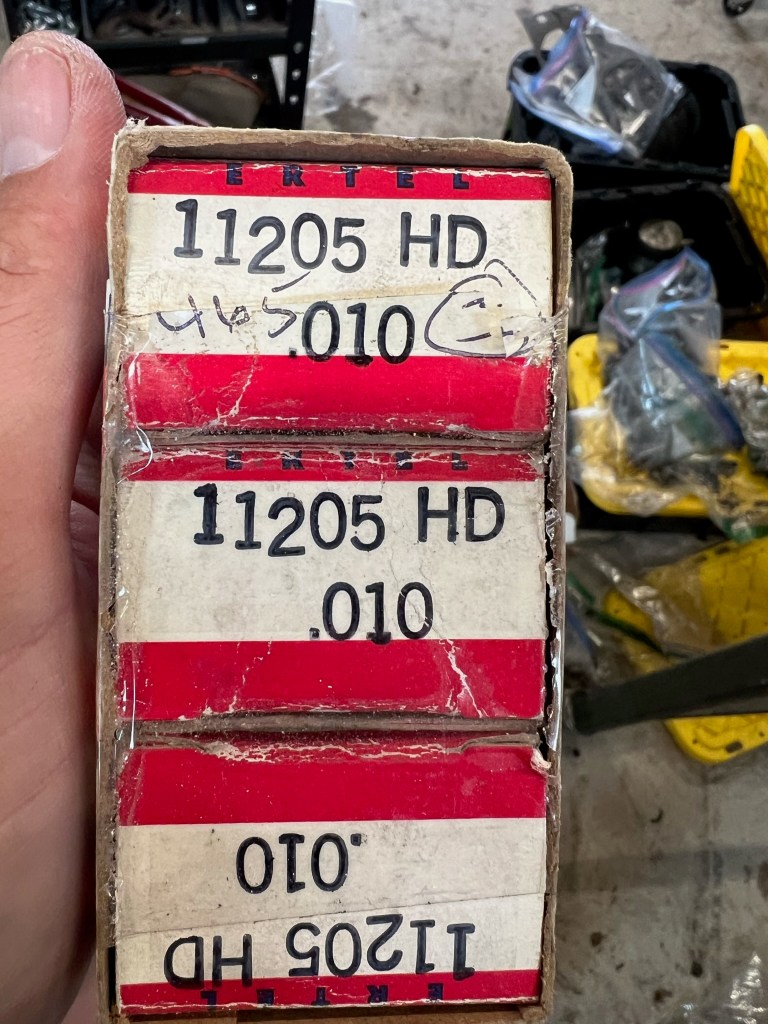

New parts all prepped and waiting to go in.

And the rebuild begins!

Welp, these old bearings sitting on the shelf were pure shit. Company sent me a new set.

Wrong piston laid next to the original. While these pistons would’ve worked because they are for the same engine, they were generator pistons and took different rings that weren’t available.

Now these bearings look good to go!

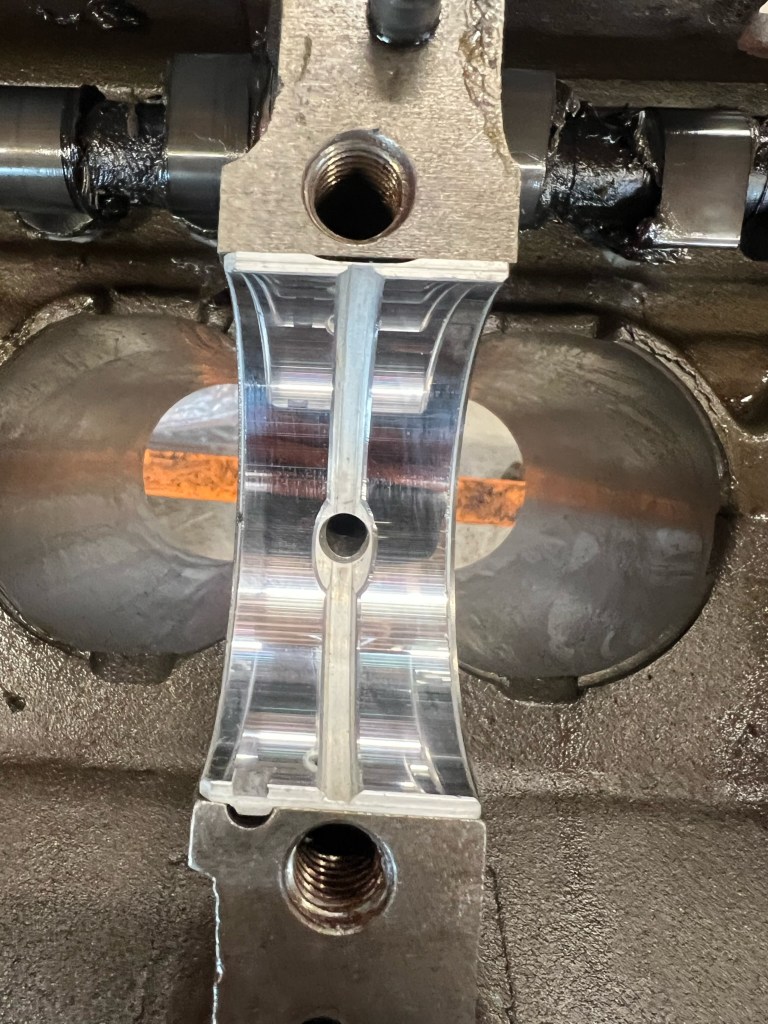

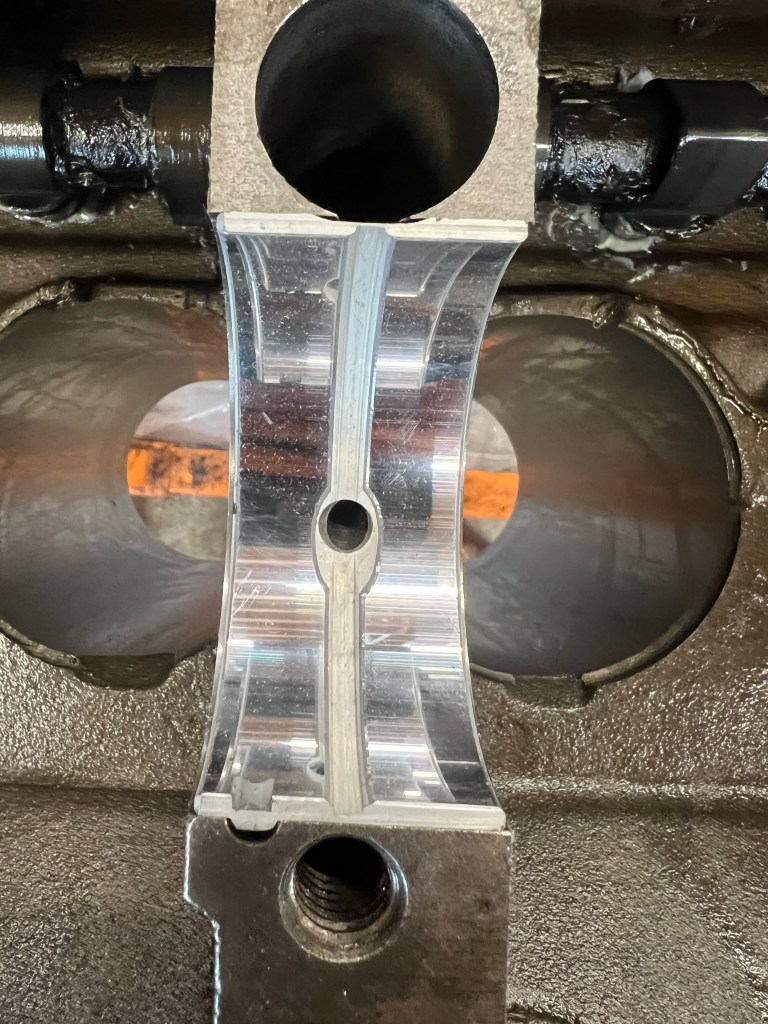

Checking bearing clearances on every surface.

Cracked main brace. A little tig welding and this was fixed.

DO NOT FORGET TO PLUG THIS!!!!

Freshly ground crank dropped in. This thing is heavy as hell and hard to drop in gently without scraping anything.

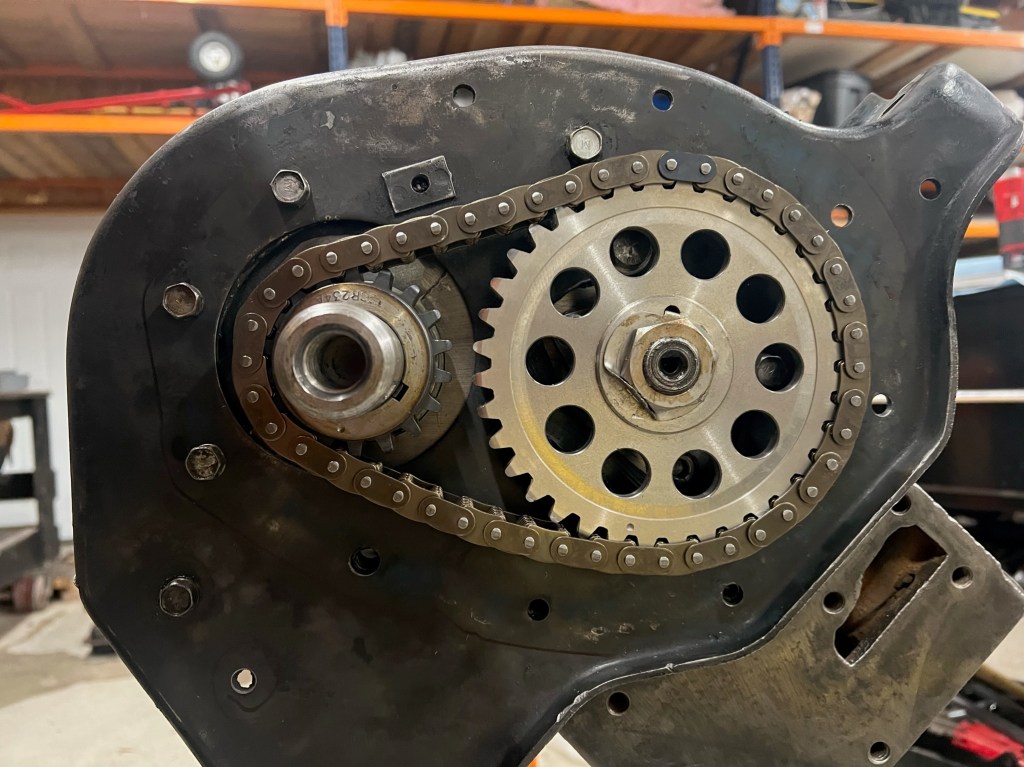

Timing chain and gear photos for reference.

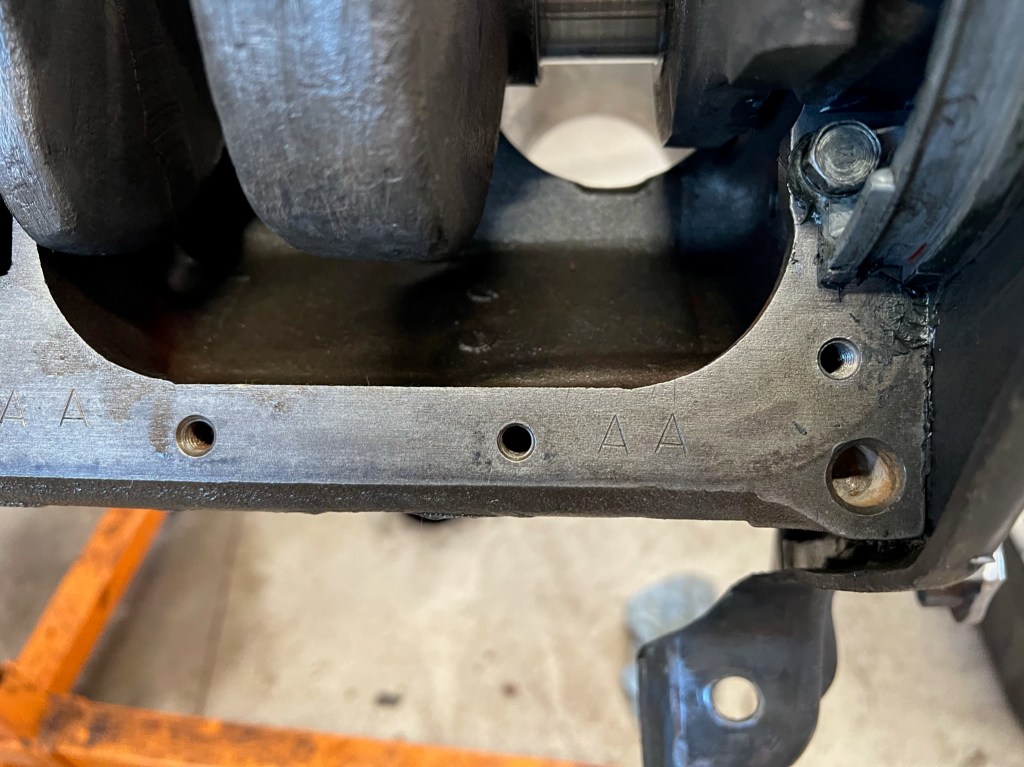

Factory markings from 1954 calling out the bearing tolerances.

Long block is back together!

The correct pistons arrived.

Assembled

Sent home!

Old Timing gears upon further inspection needed to be replaced so a new set was ordered.

Starting engine paint with primer/adhesion promotor.

Overdrive pulled to start rebuilding.

Transmission about to come apart.

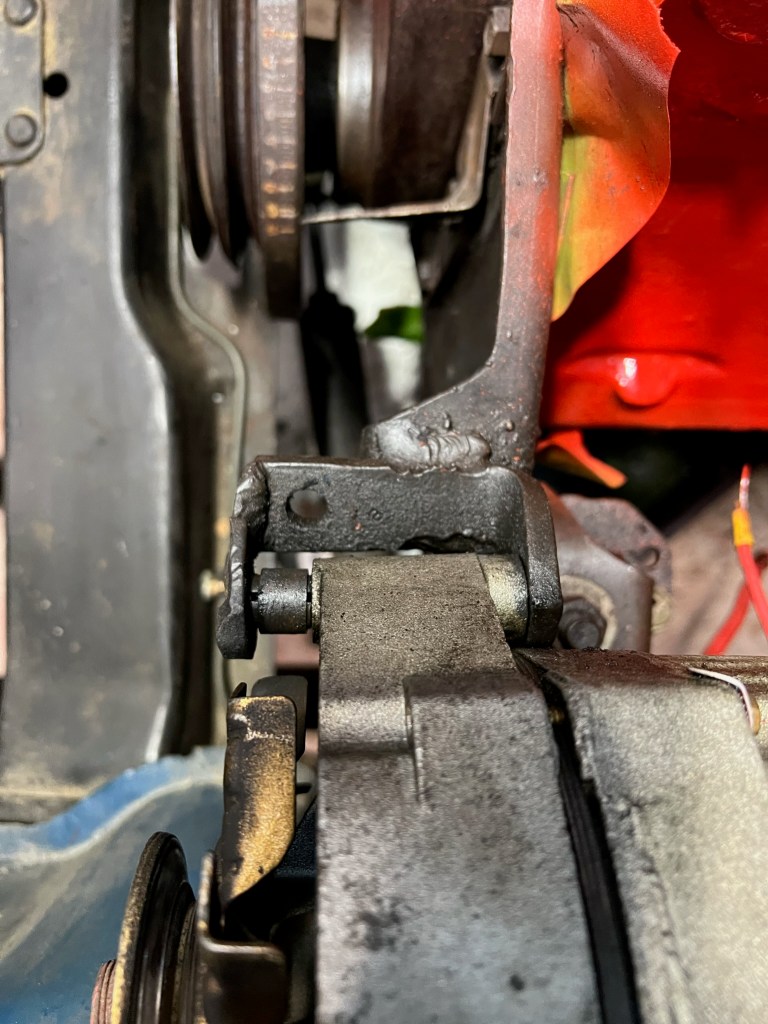

Clutch lever reference photos.

Sniper EFI!

ohhhhhh the engine is looking sweet!!!

Blank slate.

Tank dropped and modified for EFI.

Fully rebuilt Trans, Transfercase and Overdrive. Wish I took photos during the process but I was too zoned into the instructions making sure I didn’t miss something.

And she’s back together!!!

Now that is a smooth runner. Beer bottle smoothness test!

Back in action for yard work hauling branches around the mountain!!!

Wasn’t happy with out it was running so I put a newer distributor on it.

And then after 2 years of my dad bugging to me buy this truck once it was done, I decided to let it go… It now lives with him so its not completely out of my life.

Cleaning and packing it up for the trip

Sometimes I can be funny.

Loading it up on the trailer (backwards) there was too much weight of parts in the bed to pull forward.

The end for now!

Leave a comment